Optimising production using 3D models

Client: Walkersteel Engineering

Summary

Supporting British engineering WalkerSteel Engineering Services by developing sheet metal products from general arrangement drawings to comprehensive manufacturing information using 3D modelling while optimising metal stock for minimal wastage.

Project

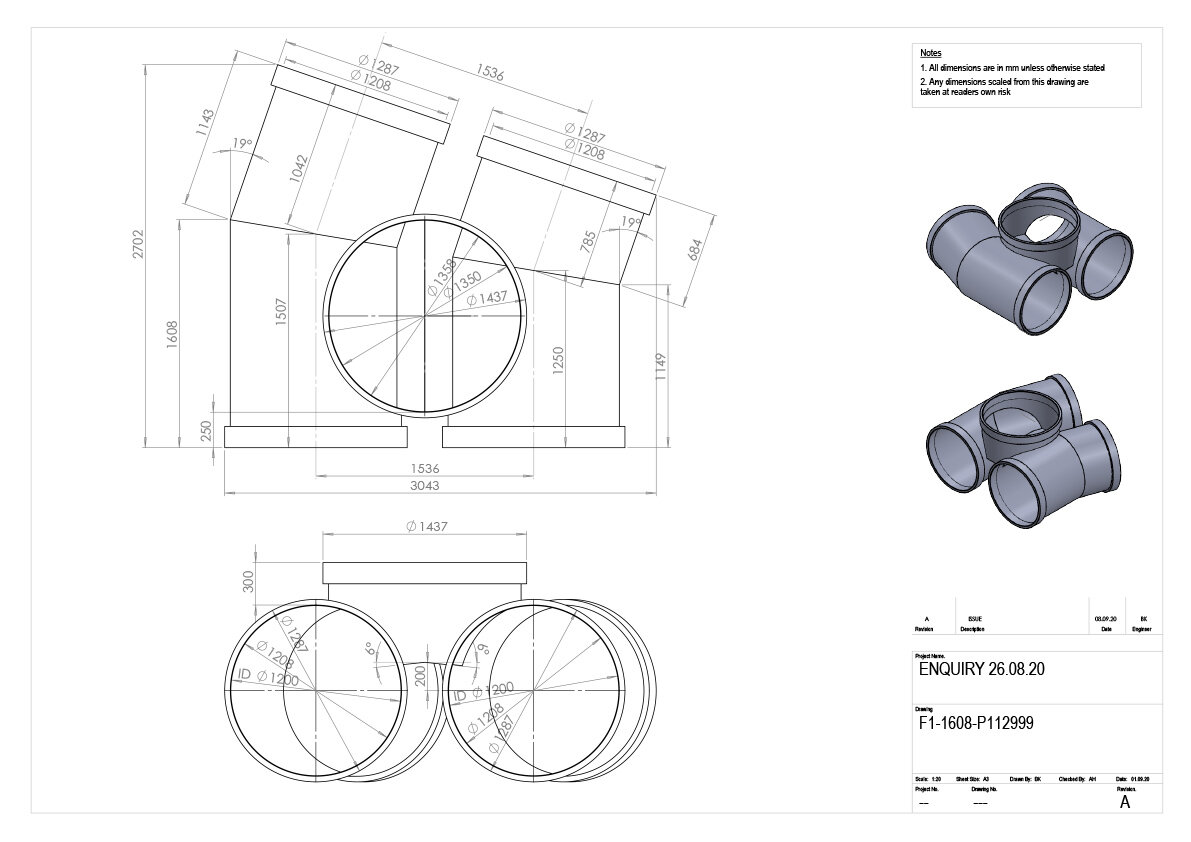

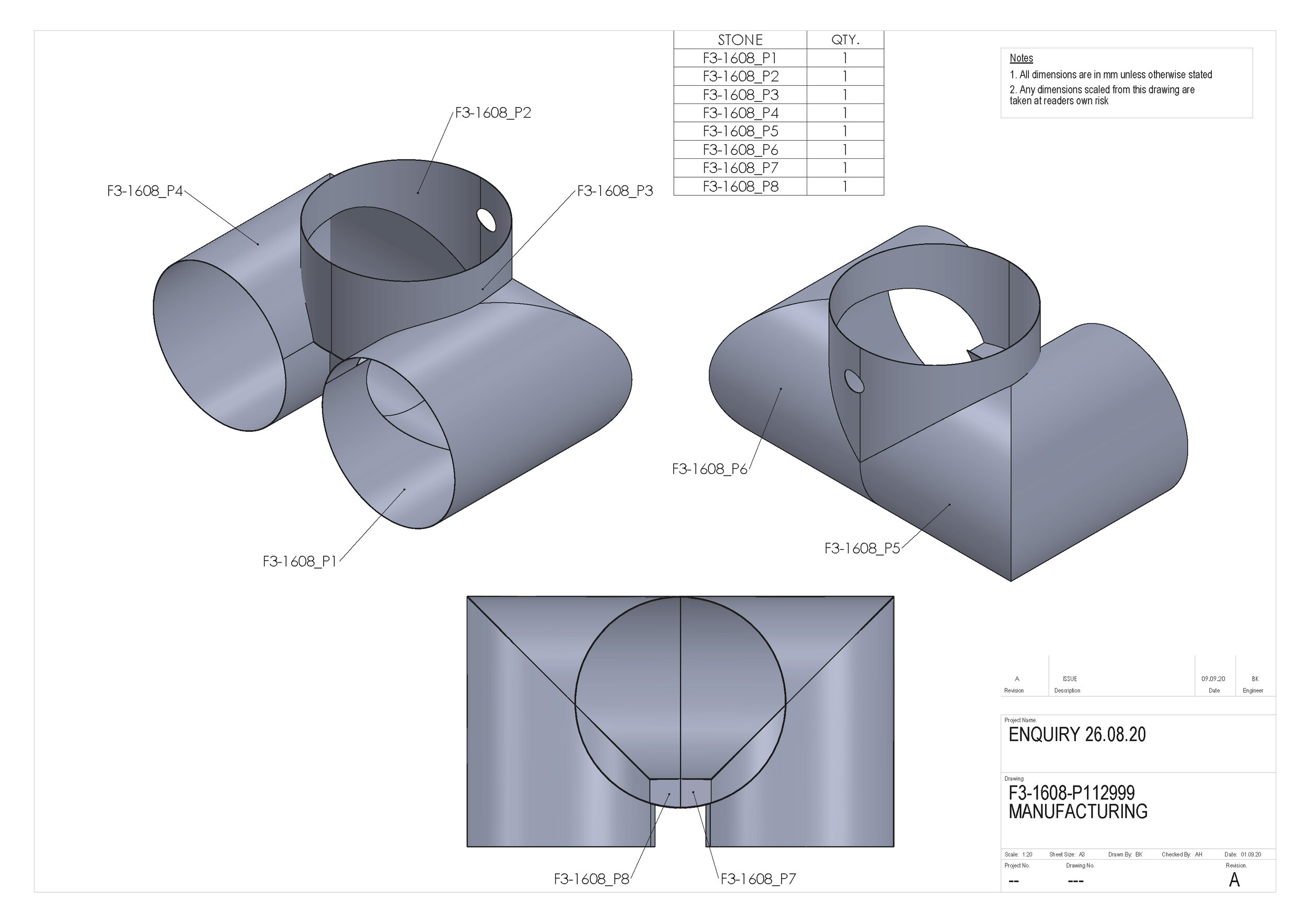

Walkersteel Engineering is a sheet metal fabricator primarily creating below-ground storage tanks which are made up of pipe sections upto Ø1800 internal diameter. Generally the sections are fairly standard, however the connections and access points are complex.

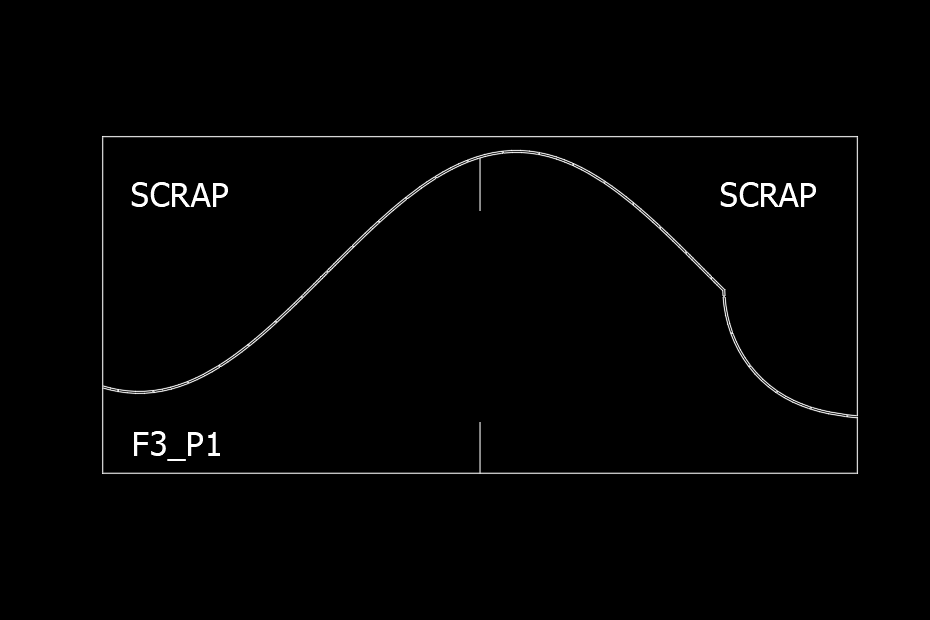

We were given a basic general arrangement drawing of these tank sections, and from this we created a 3D model that could then be processed into creating the flat profiles required to create the unit. We then arranged the profiles on sheet metal stock sizes as to optimise the available steel with as little waste as possible from the laser cutting process. We also provided the bend and assembly weld drawings to deliver a complete solution.